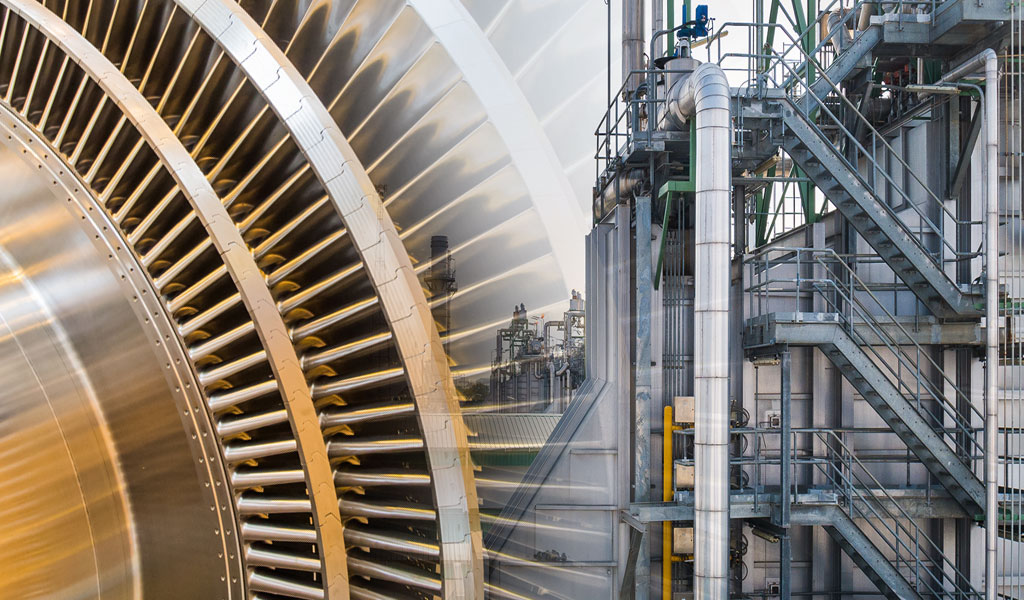

Power Generator Applications

POWER GENERATION Applications

From our industry leading position in the design and manufacture of harness and sensor products for the aviation market, HarcoSemco has developed a line of innovative, customized, industrial and marine solutions for both on and off-engine applications in demanding power generation environments.

From the OEM supply of electrical harnesses to the aftermarket supply of temperature and speed sensors, our product designs are based on exacting OEM specifications and can be found across a wide range of land and marine platforms.

Electrical Harnesses

HarcoSemco custom-designed electrical harnesses offer packagers, operators and suppliers of GE LM Series gas turbines, reliable, cost effective solutions for the most demanding industrial and marine applications. Designed, tested and approved for installation in hazardous locations, all HarcoSemco harnesses are ATEX & UL/CSA listed.

Offering both on and off-engine application for the LM Series turbines, our harness assemblies utilize stainless steel connector/back shell configurations and incorporate rubber over-molding at the cable transitions. Coupled with EMI shielding techniques, flexible cable lay-ups and abrasion-resistant, machine-applied braid applications, the HarcoSemco LM Electrical harnesses are well suited for the harsh environments typical of the installation.

Features

- Potted and over-molded connector to cable transitions

- Machine-applied, abrasion-resistant braid over stainless steel EMI shield

- Custom harness lengths, jacket color coding and laser marking

Benefits

- Fluid ingress/immersion proof

- Chafe resistant

- Vibration & heat tolerant

- Rugged/flexible design

- High reliability

Applications

- LM1600/2500/5000/6000/LMS100

EGT Harnesses

HarcoSemco exhaust gas temperature (EGT) harnesses are designed for ease of installation and rugged service life. Constructed to maintain flexibility and long life, each assembly is fabricated using 19 strand, 17 gage, and high accuracy thermocouple grade conductors. Each conductor is insulated with a combination of mineral and fiberglass materials chosen specifically to provide electrical isolation and mechanical support under high vibration and extreme temperature environments. Each cable is electrically balanced to maintain circuit resistance and features welded junctions and contacts. In-house capability allows HarcoSemco to utilize a variety of jacket materials, as well as high temperature outer braids, and over-molded connectors for lower temperature applications, depending on your requirements. The standard EGT harnesses utilize a machine applied, stainless steel outer braid that provides low impedance shielding and chafe protection in a highly flexible configuration. Connection to the EGT harness is accomplished using high-temperature military grade connectors and gold-plated, four-tine contacts to ensure thermocouple circuit integrity.

Features

- Potted and over-molded connector to cable transitions

- Machine-applied, high temperature braiding for chafe and EMI shielding

- Integral thermocouple probes – flex to rigid transition

Benefits

- Chafe resistant

- Vibration & heat tolerant to 1000°F

- Rugged/flexible design

- High accuracy and reliability

Applications

- LM1600/LM6000/FT8/FT4000/GG8

Thermocouple Sensors

Individual thermocouple sensors are available with an exposed junction for quick response or an enclosed insulated junction for exhaust gas environments. Rugged construction assures low life cycle cost and high reliability. For use in averaging or individual multiple depth sensing. Available with standard thermocouple alloy studs, output terminals, hermetically sealed connectors or flexible leads.

HarcoSemco hermetically sealed EGT probes have demonstrated consistent, trouble-free performance with around-the-globe installations, and provide individual or averaging of temperatures at multiple immersion depths. Resistance balanced for true electrical average. In typical applications, multiple EGT probes are connected to a single flexible harness. This provides the ability to easily replace individual probes, reducing cost and turbine downtime.

Features

- Sensor temperature ranges from -65° to +2000°F

- Output terminations to 1000°F

- Hermetically sealed construction

- Individual or flexible lead connections

Benefits

- High accuracy

- Individual or averaging thermocouple signal

- Flexible design with individual probes

- High reliability

Applications

- LM1600/2500/5000/6000

- FT4

- 6B/7E/7EA/7FA/7FB/9E/9EA/9FA/9FB

Resistance Temperature Detectors

HarcoSemco RTDs for power generation; derived from our aerospace applications, have been engineered for the most demanding environments and deliver high accuracy temperature detection and proven reliability. RTDs operate on the principle of a material’s electrical resistance change with temperature. The HarcoSemco RTDs typically use platinum elements due to their excellent sensitivity, accuracy and temperature range characteristics.

HarcoSemco immersion RTDs are interchangeable with lube RTD sensors located in the gas turbine’s lube gearbox assembly; TGB, AGB, sumps (A-E) and supply.

Features

- High accuracy platinum-wound elements

- Hermetically sealed construction

- One-piece sensor tip construction

- Temperature range -40° to +400°F

Benefits

- Fast linear response

- Excellent stability

- Low maintenance/High reliability

Applications

- Engine fuel

- Engine bearing oil

- Hydraulic fluids

Magnetic Speed Sensors

HarcoSemco magnetic speed sensors convert motion to an electrical signal without external power requirements. Housed in a one-piece stainless steel assembly, our speed sensors provide extreme high accuracy and have no moving parts. Designed and manufactured to aerospace quality standards, they are ideally suited for high performance in demanding extremes of temperature, vibration, and contaminant exposure. The magnetic speed sensors are interchangeable with XN25 sensors found in transfer and gearbox section of LM Series gas turbines.

Features

- Pressure: 10-15 psai

- Hermetically sealed, one-piece construction

- Temperature: -65° to +350°F

- High shock resistance

Benefits

- High positional accuracy

- Extended temperature range

- Low-cost redundancy/maintenance

Applications

- Engine RPM

- Transmission speed

- Engine control systems

- Wheel speed